about

Tool and die makers create specialized custom tools, metal molds, and precision parts that factories use to manufacture products like electronics, appliances, or medical devices with perfect accuracy and repeatability. They work in industrial shops, labs, or production facilities using advanced machines to shape and assemble durable metal components. Their expertise is vital today because factories rely on these precisely crafted tools to produce high-quality goods efficiently, reducing waste and costs across automotive, aerospace, and consumer industries. Choosing this career means solving complex technical challenges while enabling mass-scale innovation—from building smartphone casings to repairing essential machinery that keeps assembly lines running reliably every day.

day in the life

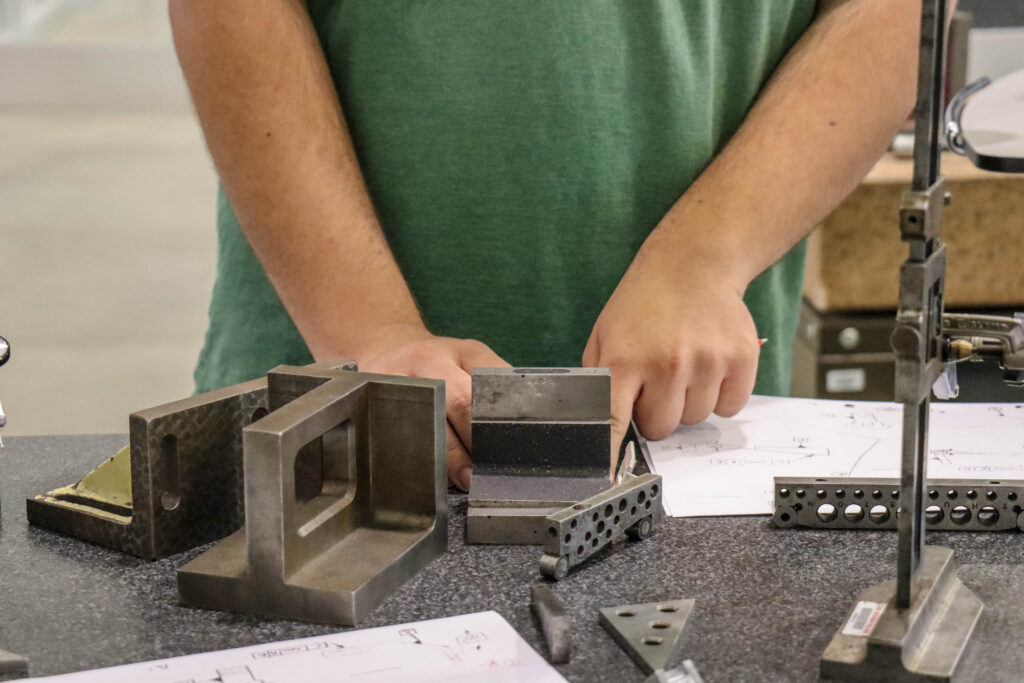

Tool and die professionals plan their day using detailed product designs, then carefully carve or grind solid metal blocks into precise shapes using specialized cutting machines and measurement tools. They solve challenging puzzles daily, ensure fit, form and function within hair-thin tolerances or strengthening weak areas to withstand repeated production cycles. Their interactions include troubleshooting design details with engineers, collaborating with teams to assemble finished tools, and advising staff on proper handling to prevent damage. The tangible reward comes when visiting production lines, seeing crisp plastic components released from a mold they built, or watching hundreds of phones snap together perfectly every hour thanks to their tool creations.